The Elements of Power: How Rare Earth Elements Are Shaping the Future of Technology, Geopolitics, and the Planet

- Team Arterial

- Aug 27, 2025

- 7 min read

Updated: Aug 31, 2025

A state-of-the-art electric vehicle glides past, a silent testament to a cleaner future. Far away, the colossal blades of a wind turbine slice through the air, harvesting green energy from the sky. These are the icons of our 21st-century ambitions: a world that is smarter, more connected, and sustainable. Yet, hidden deep within the powerful motors, vibrant screens, and sophisticated electronics that define this new era lies a profound paradox. Our gleaming, digital, and green future is built upon a foundation of 17 obscure metallic elements—the so-called rare earths—whose journey from deep within the Earth’s crust to our most advanced devices is fraught with geopolitical tension, staggering environmental costs, and complex economic warfare.

The global struggle to discover, extract, and control these elements is no longer a niche industrial concern but a defining challenge of our time. The pursuit of decarbonization, the drive for technological supremacy, and the imperatives of national security all converge on this unique group of metals.

The Alchemist's List: The Indispensable Ingredients of Modernity

The journey into the world of rare earth elements (REEs) begins with correcting a fundamental misunderstanding. Their name is a misnomer. This group of 17 elements—the 15 lanthanides on the periodic table, plus scandium and yttrium—are not, in fact, geologically rare. Cerium, the most common REE, is more abundant in the Earth's crust than copper. The "rarity" stems from a different challenge: these elements are seldom found in concentrated, economically minable deposits. They are widely dispersed, often mixed together in complex mineral deposits, making their separation and purification an arduous and costly undertaking. This economic and technical "rarity," rather than geological scarcity, is the source of their strategic value. Their unique atomic properties—which grant them unparalleled magnetic, luminescent, and catalytic powers—have made them the indispensable "vitamins" of modern technology.

The device on which you are reading this is saturated with rare earths. The powerful, miniature neodymium-iron-boron (NdFeB) magnets in smartphone speakers and computer hard drives allow for high performance in a compact size. The vibrant colors on LED screens are produced by phosphors made from yttrium, europium, and terbium, while high-quality camera lenses rely on lanthanum.

This dependency extends to the green transition. The same powerful NdFeB magnets are the heart of the lightweight, high-efficiency motors that propel electric vehicles and the massive generators in modern wind turbines. A single EV can require kilograms of lanthanum for its battery, while a large wind turbine can contain hundreds of kilograms of neodymium and dysprosium.

Finally, and perhaps most critically, is national security. The battlefield of the 21st century is electronic, and REEs are non-negotiable components of modern defense systems. Samarium-cobalt (SmCo) and NdFeB magnets are critical for the actuators in precision-guided munitions, enabling unparalleled accuracy. Advanced radar, sonar, and electronic warfare systems rely on these magnets for signal amplification. The F-35 fighter jet contains over 400 kg of REEs for its targeting lasers, flight controls, and stealth capabilities, while night-vision goggles use phosphors made from europium and yttrium.

Element | Key Property | Critical Application(s) |

Neodymium (Nd) & Praseodymium (Pr) | Extreme Magnetic Strength | Permanent Magnets (EV Motors, Wind Turbines, Hard Drives) |

Dysprosium (Dy) & Terbium (Tb) | High-Temperature Magnetism | Additives to NdFeB magnets for durability in high-heat environments (EVs, Defense) |

Yttrium (Y) & Europium (Eu) | Luminescence (Phosphors) | Red colors in LED/OLED screens, Lasers, Radar systems |

Lanthanum (La) & Cerium (Ce) | Catalytic & Optical Properties | Oil Refining Catalysts, Catalytic Converters, Camera Lenses |

List of 17 Rare Earth Elements

The Dragon's Hoard: China and the Geopolitics of a Global Monopoly

The story of rare earths in the modern era is inseparable from the story of China's rise as an industrial superpower. In 1992, paramount leader Deng Xiaoping famously declared, "The Middle East has oil, China has rare earths". This was a statement of strategic intent. Over the subsequent decades, China executed a deliberate industrial policy to dominate the global REE market. The result is a staggering monopoly: today, China accounts for approximately 70% of global REE mining and, far more critically, 85-90% of the complex mid-stream processing and refining that transforms raw ore into usable metals and alloys.

China's strategy was not built on geology alone. Its dominance comes from its mastery of the entire value chain, achieved through massive state subsidies, insufficiently enforced environmental regulations that allowed it to drastically undercut global competitors, and the strategic acquisition of Western technology. A key moment was the 1997 purchase of Magnequench, a General Motors subsidiary and a leader in magnet technology, which effectively transferred critical intellectual property to Chinese control.

This control over processing is the keystone of China's power. For years, countries like the United States and Australia could mine their own rare earth ores, but they were often forced to ship them to China for the final, most technologically complex stages of separation and magnet manufacturing. China's monopoly is not one of resources, but of processing and manufacturing—a far more resilient form of control.

With this monopoly secured, China has not hesitated to use it as a geopolitical lever. In 2010, it enacted an unofficial embargo on REE exports to Japan amid a diplomatic dispute, sending shockwaves through global technology markets. More recently, it has deployed a sophisticated strategy of export controls and licensing requirements targeting the United States and India. This "on-off" export strategy is a calculated form of economic statecraft. A total ban would trigger a massive global effort to build alternative supply chains. Instead, a policy of intermittent, unpredictable restrictions creates extreme price volatility and paralyzes private investment in the West, preserving China's long-term leverage.

Country wise Rare Earth element potential:

Country | Estimated Reserves (Metric Tons REO) |

China | 44,000,000 |

Vietnam | 22,000,000 |

Brazil | 21,000,000 |

Russia | 21,000,000 |

India | 6,900,000 |

Australia | 4,200,000 |

United States | 2,300,000 |

(Source: U.S. Geological Survey, Mineral Commodity Summaries 2024 ) |

The Race to Diversify: Case Studies from the New Front Line

The world has awakened to the risks of this dependency. Across the globe, governments and private companies are now engaged in a frantic race to build alternative, resilient supply chains.

India's Awakening – A Quest for Mineral Self-Reliance

India finds itself in a paradoxical position. It possesses the world's fifth-largest REE reserves, primarily in monazite beach sands, yet it remains heavily dependent on Chinese imports for finished products like high-strength magnets. This vulnerability has been starkly exposed by recent Chinese export curbs.

India's path to self-reliance is uniquely challenging. Its reserves are intertwined with radioactive elements like thorium, placing REE policy under the strict purview of the Department of Atomic Energy (DAE). For decades, the state-owned Indian Rare Earths Limited (IREL) has managed this sector, mastering mining and basic separation but lacking the capacity for producing advanced alloys and magnets. In response, the Indian government has launched the National Critical Minerals Mission (NCMM). This represents a fundamental strategic shift, aiming not merely to increase mining but to build an entire domestic value chain. The mission seeks to fast-track exploration, encourage private sector participation, and secure resources abroad through state-backed entities.

The Phoenix of the Mojave – The Revival of America's Mountain Pass Mine

The story of the Mountain Pass mine in California is a cautionary tale and a symbol of American industrial revival. From the 1960s through the 1980s, this single mine was the world's leading producer of rare earths. However, by the 1990s, it could no longer compete with low-cost, state-subsidized Chinese production and ceased operations in 2002. A subsequent attempt to revive it under the company Molycorp ended in a 2015 bankruptcy, a direct casualty of China's price manipulation.

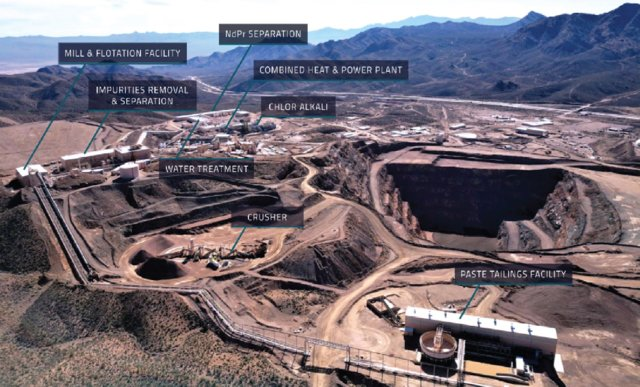

In 2017, the mine was reopened by a new entity, MP Materials. Yet, for years, it perfectly illustrated the West's core vulnerability: it mined the ore in California but had to ship the concentrate to China for the critical separation and refining steps. Backed by funding from the U.S. Department of Defense, MP Materials has now built its own separation facilities on-site and is constructing a magnet manufacturing factory in Texas. This represents the first significant attempt in the Western world in decades to rebuild a fully integrated, "mine-to-magnet" supply chain.

The True Cost of Progress: The Environmental and Human Scars

The clean hum of an electric vehicle highlights a dirty secret: the process of extracting rare earths is one of the most environmentally destructive forms of mining. The current economic model has been built by offloading the immense environmental and social costs of production onto local ecosystems and communities.

In open-pit mining, topsoil is removed to access the ore, which is then drenched in powerful chemicals in vast leaching ponds. The waste-to-product ratio is staggering: producing one ton of rare earth oxides can generate up to 2,000 tons of toxic waste, including wastewater laced with acids, heavy metals, and radioactive residue from co-located elements like thorium and uranium.

The city of Baotou in China's Inner Mongolia, the world's rare earth capital, serves as a grim case study. Decades of largely unregulated mining have created a toxic landscape where the soil and water are heavily polluted with arsenic and fluoride, leading to widespread health crises in the local population. The human toll is severe, with workers and residents suffering from respiratory diseases, cardiovascular problems, and skin ailments. China has even acknowledged the existence of "cancer villages," where rates of cancer are disproportionately high due to industrial pollution.

In the face of these costs, recycling—or "urban mining"—presents a compelling alternative. Currently, a mere 1% of rare earths are recycled from end-of-life products. The challenges are significant, as the elements are used in minuscule quantities, making extraction difficult and expensive. However, research suggests recycling can have less than half the carbon footprint of primary mining. A breakthrough in this field could be a geopolitical game-changer, creating a secure, domestic source of critical materials independent of traditional mining.

Redesigning Our Material Future

We stand at a crossroads, defined by a core conflict: the very elements indispensable for a "clean" energy transition are sourced through processes that are environmentally destructive and geopolitically weaponized. The path forward requires a comprehensive strategy that moves beyond simply digging more mines. It requires diversification to build resilient and ethical supply chains, innovation in substitution and efficiency, and a massive investment in recycling technologies to make "urban mining" a scalable reality.

The urgency is clear. Driven by the growth in electric vehicles and wind power, global demand for the critical magnetic rare earths is projected to triple by 2035. Closing the potential supply gap sustainably and securely is one of the great challenges of our time. The true test of 21st-century innovation lies not just in creating revolutionary products, but in fundamentally redesigning the material systems that bring them to life.

Comments